|

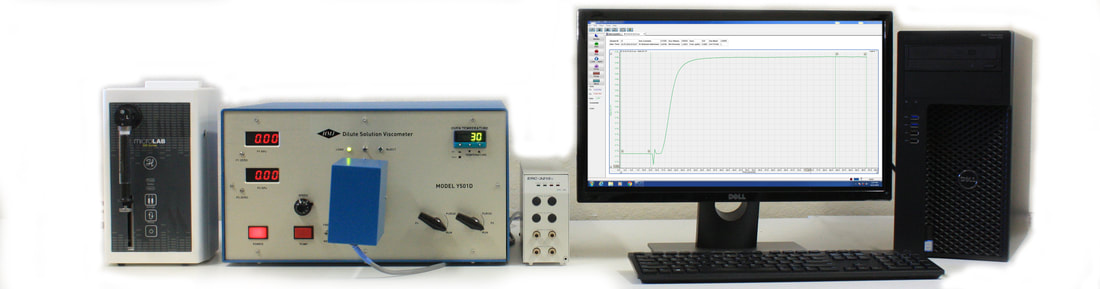

The Relative Viscometer was specifically developed to measure the viscosities of dilute polymer solutions.

It provides faster analysis, greater precision, and less solvent exposure compared to conventional glass tubes. The Relative Viscometer is ASTM-approved, and its closed-loop system provides greater operator safety than conventional glass tubes. |

Solution viscosities are determined by the viscosity of the sample relative to the reference solvent. The Relative Viscometer measures the solvent and sample viscosity simultaneously, avoiding errors due to temperature fluctuation and solvent variations.

It is the only solution viscometer that can provide Relative, Intrinsic, Inherent, Specific, and Absolute Viscosity as well as Molecular Weight in a single experiment.

Typical applications include, but are not limited to:

It is the only solution viscometer that can provide Relative, Intrinsic, Inherent, Specific, and Absolute Viscosity as well as Molecular Weight in a single experiment.

Typical applications include, but are not limited to:

- Polyethylene Terephthalate (PET)

- Polyvinyl Chloride (PVC)

- Polyolefins (PE, PP)

- Polyamides (Nylon)

- Synthetic Rubber (EPDM)

- Hyaluronic Acid (HA)

|

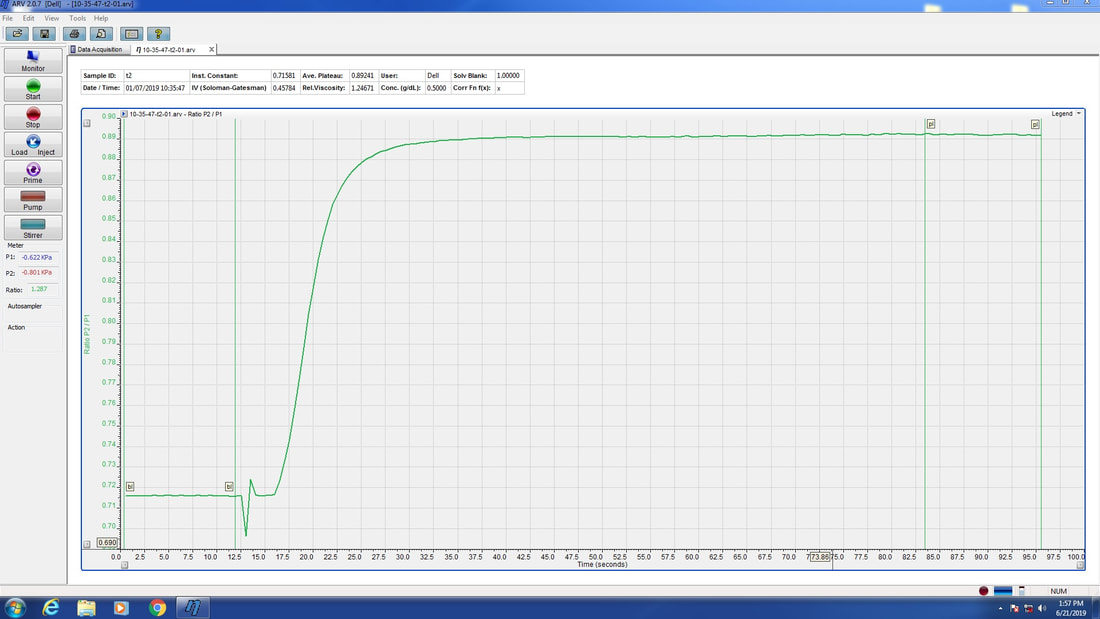

Data capture and data processing are controlled by the Data System. A screenshot of a typical sample run from the Relative Viscometer control software (ARV) is shown on the right

The relative viscosity reading (ratio of P2/P1) plateaus at around 55 seconds at remains steady for remainder of the 96-second run. This run time is typical, and we find that most samples have a run time of one to two minutes. The Data System also enables automation of many of the tasks associated with sample preparation and sample handling. These capabilities are described in more detail in the "DSV Packages" section, which describes pre-arranged systems of differing automation levels. |

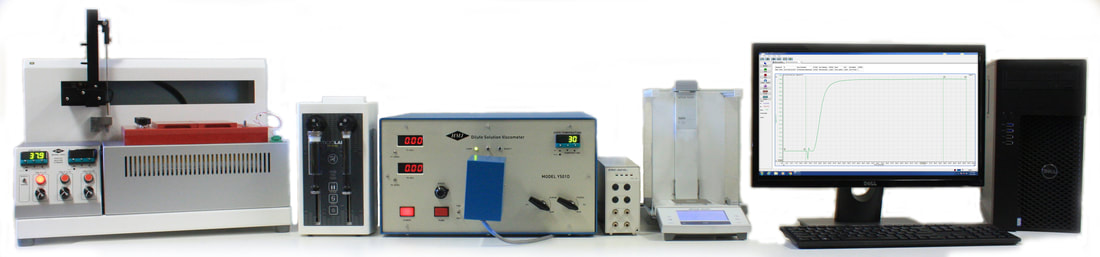

During the purchasing process, we work closely with the customer to ensure the DSV system is suited for the application. Considerations such as the following are discussed: 1) pressure range of the transducers (10, 20, or 100 kPa), 2) the material of construction for the transducers (corrosive mobile phases require special transducers), 3) the level of automation desired, and 4) the temperature of analysis (15-150 degrees C can be accommodated). If elevated temperatures are required during the sample dissolution and sampling, then the Full Automation Package with a High Temperature Option, which includes a Vortex Autosampler and a Heated Transfer Line, would be a proper choice.

As a normal part of the purchasing process, a prospective customer will typically send some of their polymer sample to our facility in Dickinson, TX so that we can provide actual data and feedback on how their polymer behaved on our system. If the data are well correlated to the customer's historical data, then this can become the basis for acceptable performance upon delivery of the DSV system to the customer's facility. At every step of the way, we aim to provide clear, prompt communication so that the customer understands what they are purchasing and is confident that the system will perform reliably at their facility.

Equipment sold by Houston MJ Associates is backed by a 1-year warranty. For new or demo equipment, allow 8 to 10 weeks for delivery after we receive the purchase order. Please browse the Products, Learning, and Support sections to learn more about DSV solutions that Houston MJ Associates offers. Technical specifications of the Y501 Relative Viscometer are listed below.

As a normal part of the purchasing process, a prospective customer will typically send some of their polymer sample to our facility in Dickinson, TX so that we can provide actual data and feedback on how their polymer behaved on our system. If the data are well correlated to the customer's historical data, then this can become the basis for acceptable performance upon delivery of the DSV system to the customer's facility. At every step of the way, we aim to provide clear, prompt communication so that the customer understands what they are purchasing and is confident that the system will perform reliably at their facility.

Equipment sold by Houston MJ Associates is backed by a 1-year warranty. For new or demo equipment, allow 8 to 10 weeks for delivery after we receive the purchase order. Please browse the Products, Learning, and Support sections to learn more about DSV solutions that Houston MJ Associates offers. Technical specifications of the Y501 Relative Viscometer are listed below.

Specification |

Value |

Measuring Principle |

Dual capillary bridge |

Measuring Ranges |

0-20 cp (mPa s) or 1-2 Relative Viscosity |

Sensitivity |

0.0001 Specific Viscosity |

Precision of RV Measurement |

+/- 1.0% relative standard deviation |

Typical Flowrate |

1-3 ml/min |

Typical Analysis Time |

2-4 min |

Typical Sample Volume |

30-35 ml for two injections |

Capillary Dimensions |

0.02" ID |

Shear Rate |

1000/sec |

Temperature Range |

15-150 degrees C |

Output Signals |

0-10 V |

Dimensions |

17.5" W x 17.5" D x 9.5" H |

Weight |

40 lbs |

Power Requirements |

120 - 240 V, 50-60 Hz, 5 A |